Welcome To SAMRIDHI POLYFILMS

Innovative Polyfilms for a Sustainable Tomorrow

Pioneering high-performance solutions with eco-friendly polyfilms for diverse industries. Discover durability, flexibility, and sustainability in every layer.

About SAMRIDHI POLYFILMS

About Us

At Samridhi Polyfilms, we are leaders in the polyfilm industry, offering high-performance, sustainable solutions tailored to the needs of various industries. With a focus on reducing environmental impact, we combine innovation with responsibility to create polyfilms that are not only durable but also eco-friendly. Optimize your agricultural operations with our high-performance films, designed for greenhouses, mulch applications, and silage wrap. Engineered to improve crop yields while minimizing environmental impact. Our industrial polyfilms cater to a variety of sectors, including construction, automotive, and electronics, providing flexible, durable, and environmentally conscious materials.

Our Products

Our Featured Products

BOPP Films

Biaxial Oriented Polypropylene (BOPP) films are engineered for optimal performance and versatility in various packaging applications. Manufactured through a unique process of casting and stretching, these films exhibit excellent clarity, a smooth surface, and outstanding chemical resistance. They are ideal for creating a moisture barrier, making them the preferred choice for food and non-food packaging.

BOPET Films

Biaxially-Oriented Polyethylene Terephthalate (BOPET) films are renowned for their clarity, stiffness, and durability. These films are produced through a precise stretching process, ensuring exceptional mechanical properties and dimensional stability. BOPET films are widely used in packaging and industrial applications, particularly where oxygen barriers and high strength are essential.

Metallized Films

Metallized films are produced by depositing a thin layer of aluminum onto BOPP or BOPET films, enhancing their aesthetic appeal and barrier properties. These films not only look visually striking but also provide excellent protection against moisture and oxygen, making them ideal for packaging that requires extended shelf life.

Coated Films

Coated films from Samridhi Polyfilms are designed to provide superior protection against moisture, oxygen, and chemicals, enhancing the longevity and integrity of packaged products. Our coated films are suitable for a variety of applications, including digital printing, labels, and high-barrier packaging, ensuring optimal performance.

PET Resin

Our PET resin is produced through an integrated process that ensures a consistent supply of high-quality raw materials for BOPET film manufacturing. This resin caters to diverse segments, including PET bottles and textile processing, providing a reliable foundation for various applications.

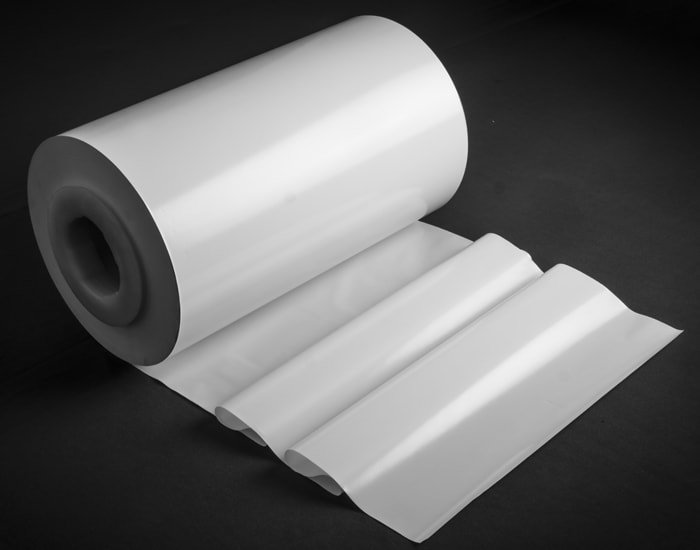

Stretch film

Stretch film is a highly stretchable plastic film commonly made from linear low-density polyethylene (LLDPE). It's used to wrap and secure items, typically on pallets, to keep them stable during storage and transportation. The film's elastic recovery helps to tightly bundle items without the need for heat, unlike shrink wrap, which requires heat to conform to the shape of the object.

Polyester

Polyester is a category of synthetic polymers widely used in the production of fibers, films, and plastics. The most common type is polyethylene terephthalate (PET), which is used to make various everyday products. Polyester is known for its durability, versatility, and resistance to shrinking, stretching, and wrinkles, making it one of the most popular materials in both textiles and packaging.

Sustainability & Innovation

We focus on developing polyfilms that provide superior performance, durability, and versatility. Whether it’s flexible packaging films, protective agricultural films, or heavy-duty industrial films, we engineer our products with precision and purpose to ensure they exceed industry standards.

For construction, automotive, electronics, and more, our industrial polyfilms are designed to meet demanding performance criteria. They offer superior strength, flexibility, and resistance to chemicals, punctures, and UV radiation, ensuring long-lasting protection in critical applications.

We offer a wide range of film thicknesses, widths, and performance features, customized to your specific application needs, from stretch films to shrink wraps and beyond.

How it works

Why Choose Us

We are committed to using recyclable and biodegradable raw materials in our polyfilm production to reduce plastic waste and environmental impact.

Our R&D team works closely with clients to develop tailored solutions that meet specific industry needs, ensuring top-notch performance and sustainability.

With state-of-the-art technology and continuous research, we push the boundaries of polyfilm design to offer products that not only meet but exceed industry standards.

As part of our commitment to a sustainable future, we prioritize the use of renewable resources, energy-efficient production methods, and waste reduction across all our operations.